TOPOCROM® coating in one process step

The TOPOCROM® surface is only deposited in closed reactor systems. After the coating preparation (inspection and cleaning of the roll) the roll is inserted into the reactor and hermetically closed. The roller then passes through the various process steps under permanent rotation. After completion of the coating, the working roll is rinsed in the reactor and then removed. It can then be used immediately in the roll stand.

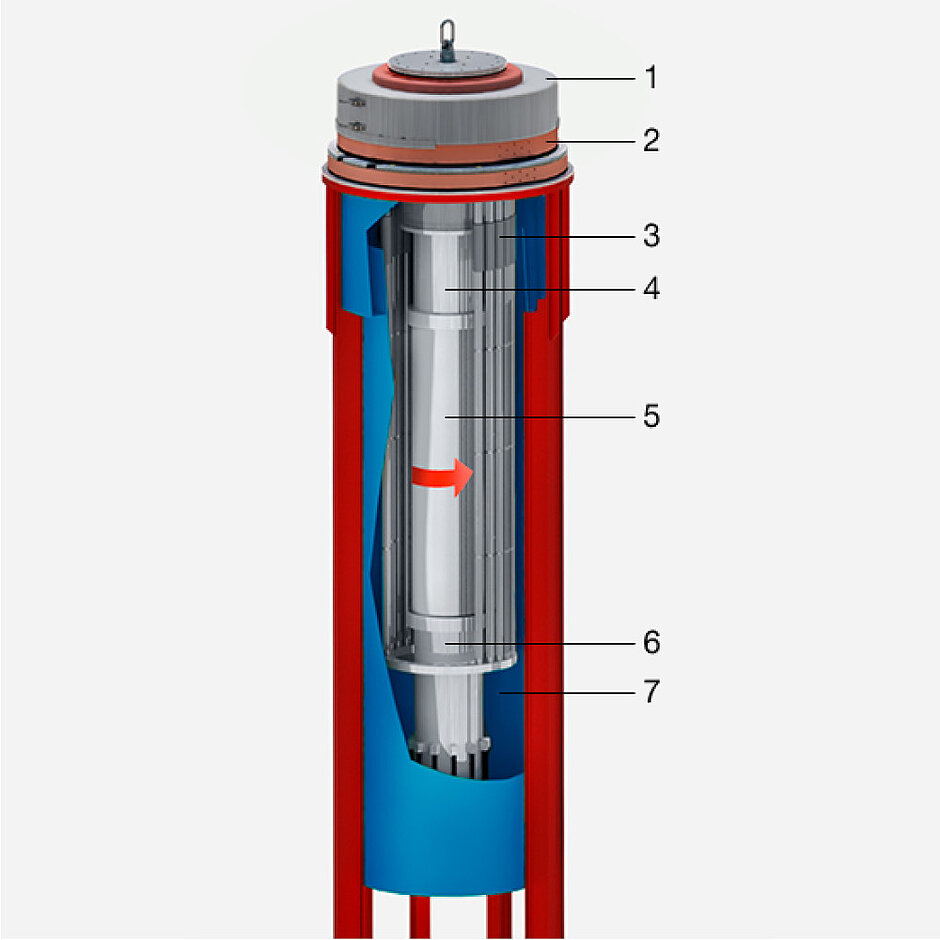

Principle of a TOPOCROM® reactor:

1. reactor head with work roll

2. power transmission element

3. anodes

4. partial cover of the roll neck

5. work-piece is rotated continually during the process

6. partial cover of the roll neck