Application in the printing industry

The multi-layer sulphamate-nickel TOPOCROM® layer is optimally matched to rollers in the printing industry. The precisely definable wettability and resistance of the TOPOCROM® surface to aggressive printing and cleaning agents are convincing and have been tried and tested for many years.

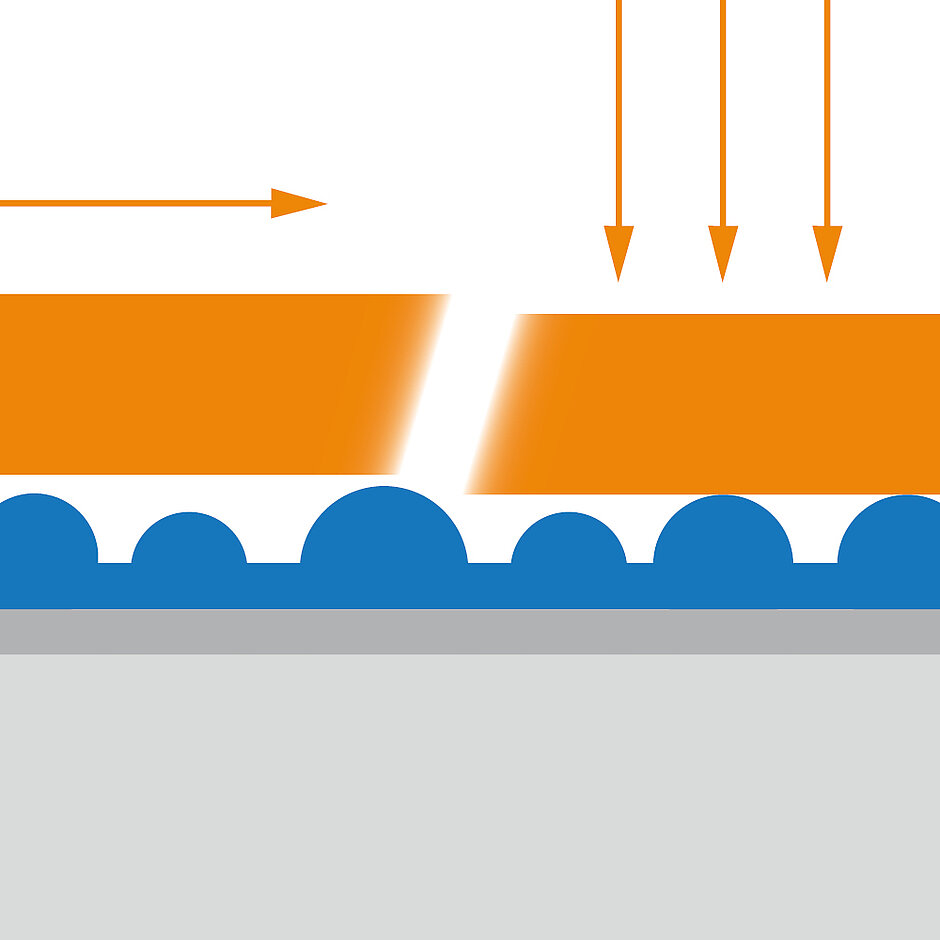

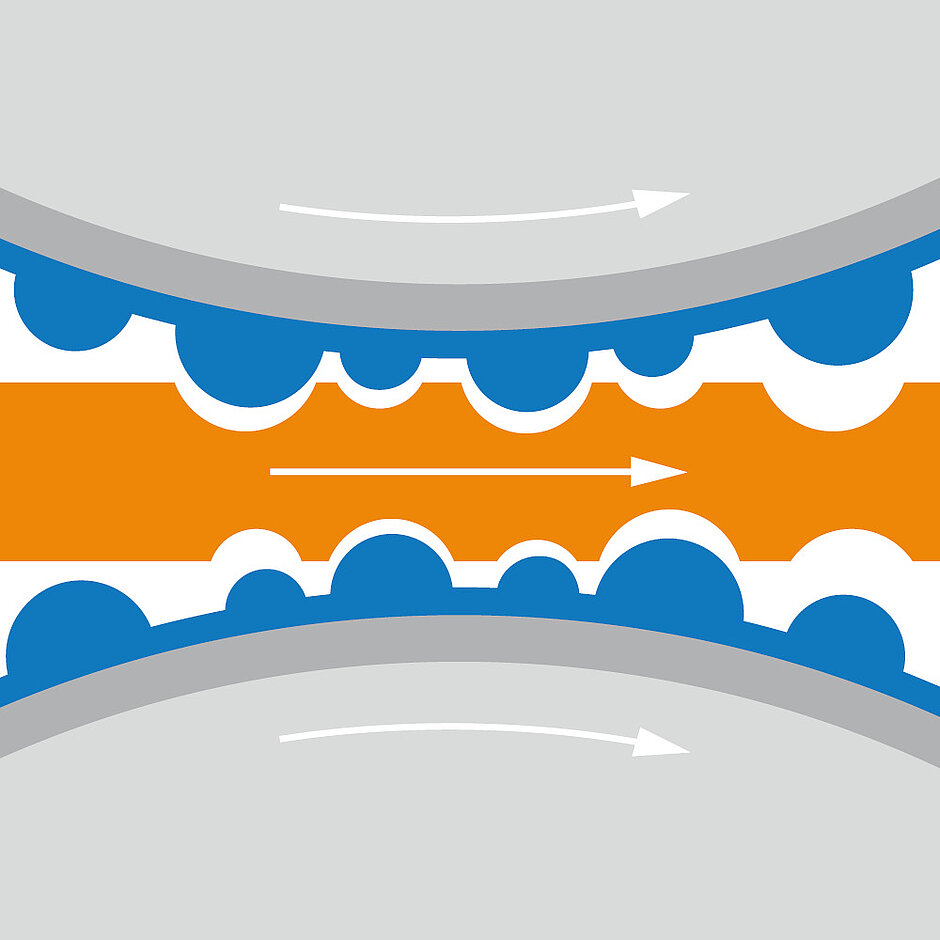

Leveller and feeder rolls: surfaces with grip for the use in the metal sheet industry

Thanks to Topocrom® coating, the rolls show an ideal feeding behaviour and reduced slip during the transport of metal strips treated with oil or lubricant. Furthermore, the service life of the rolls is significantly increased.

Test results of leveller machine manufacturers confirm:

Rolls with TOPOCROM® rollstructuring coating show the following advantages compared to conventional coating

- Excellent wear resistance

- Optimized friction coefficient

- No stick-slip effect

- Longest service life

- For feeding intensely lubricated metal sheet strips or plates only a TOPOCROM® coating offers the necessary friction

- Optimum grip, reduced slip

- Use of one single type of roll for processing different sheet surfaces

- Resilience to bending and torsion

- Transmission of torque from the roll tot he material by friction

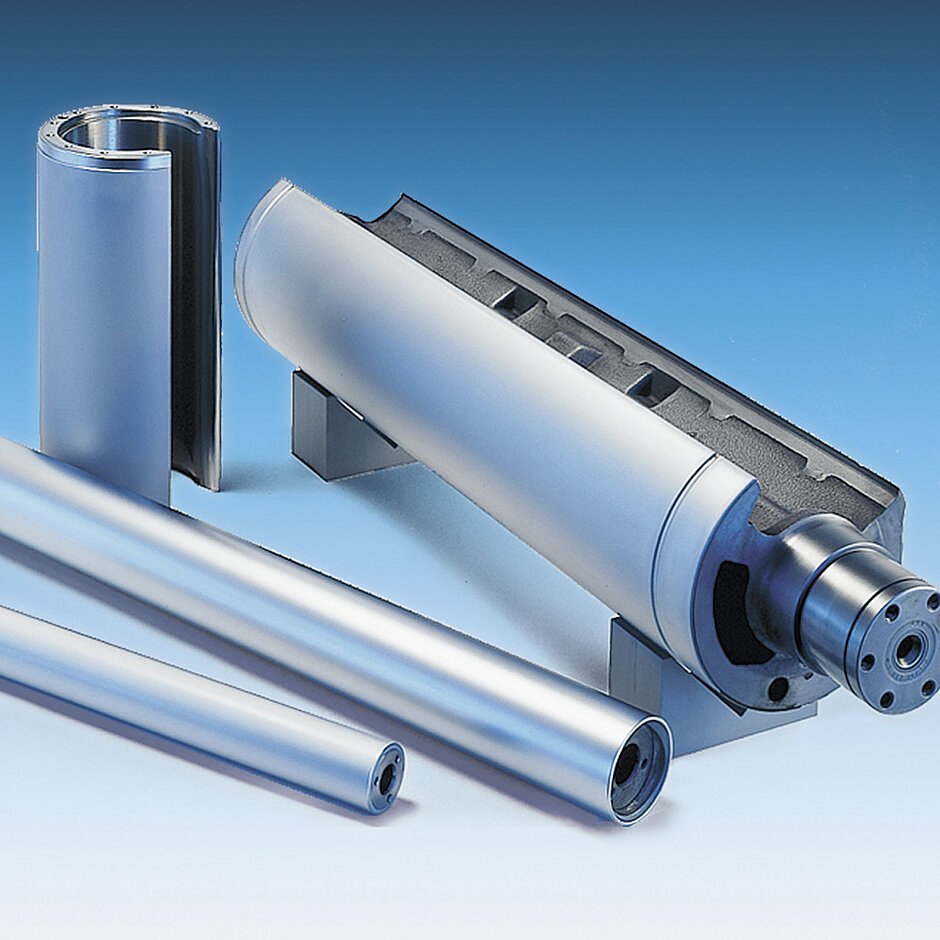

Due to the high transport weights of work rolls, many steelworks operate their own caoting facility. Please contact us for the construction of your own TOPOCROM® plant. Topocrom Systems AG supplies the suitable systems engineering.

Important advantages

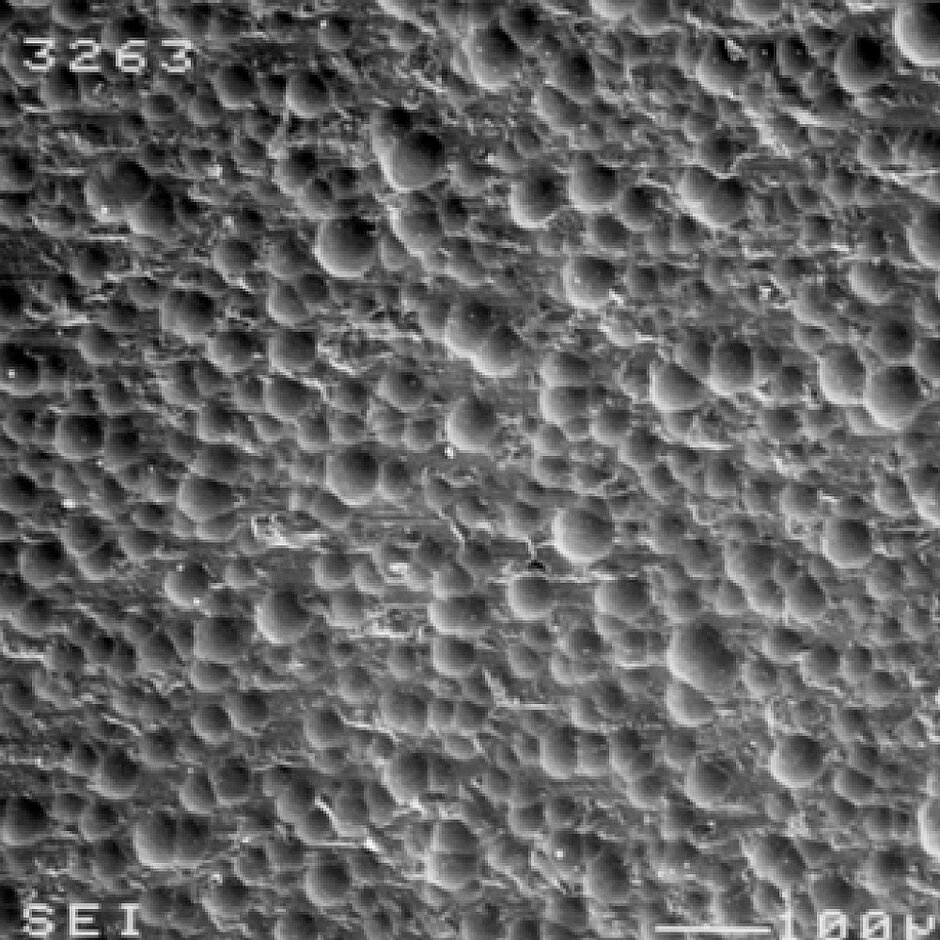

The TOPOCROM® textured thin sheet surface shows the structure transferred by the texturing roll in the form of small indentations in stochastic distribution. These sheet surfaces are particularly characterised by the variability of the surface topography. Investigation reports are available from the steel and automotive industries (delivery on request).

The appearance of the paint often gives the first impression of a vehicle and therefore is an essential quality feature of modern automobiles.

The absence of the filler in the paint structure has increased the demands on the paint and the thin sheet to which it is applied. Saving on the filler reduces processing and handling costs and, in terms of sustainability, eliminates the need for an intermediate layer.

Advantages when using TOPOCROM® coated work rolls:

- Long service life of the work rolls

- High variability of sheet metal structures

- Good painting and forming behaviour

- Low long and short wave