More production reliability through TOPOCROM® coating systems for a fibre-friendly processing of filaments

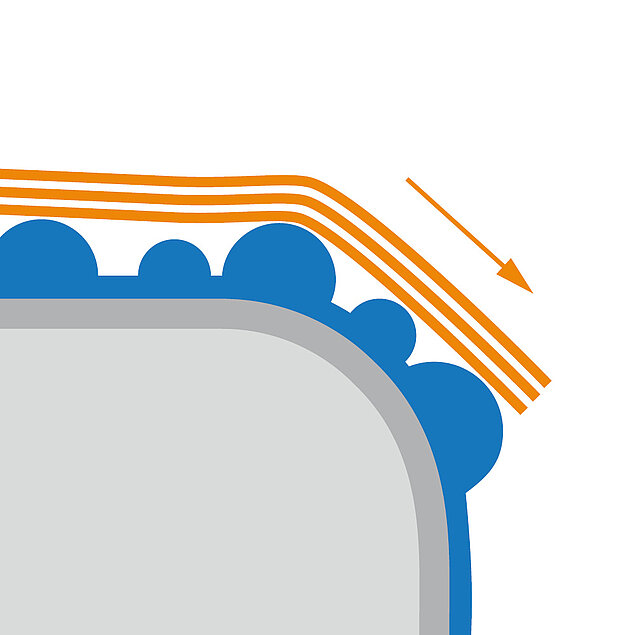

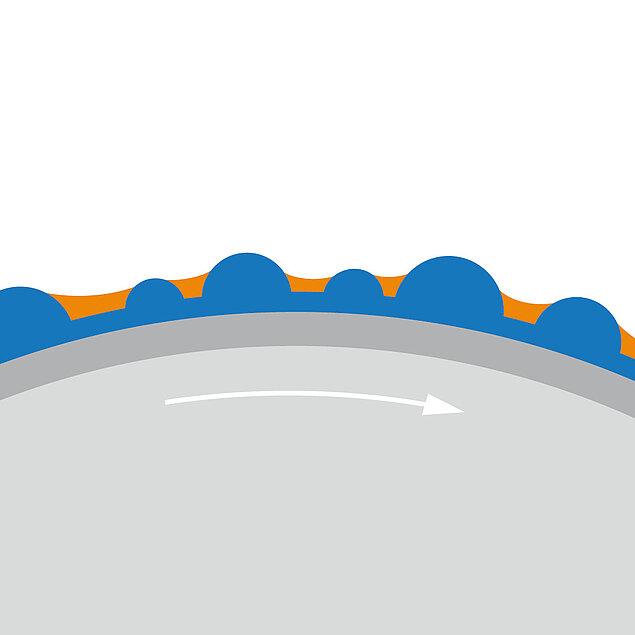

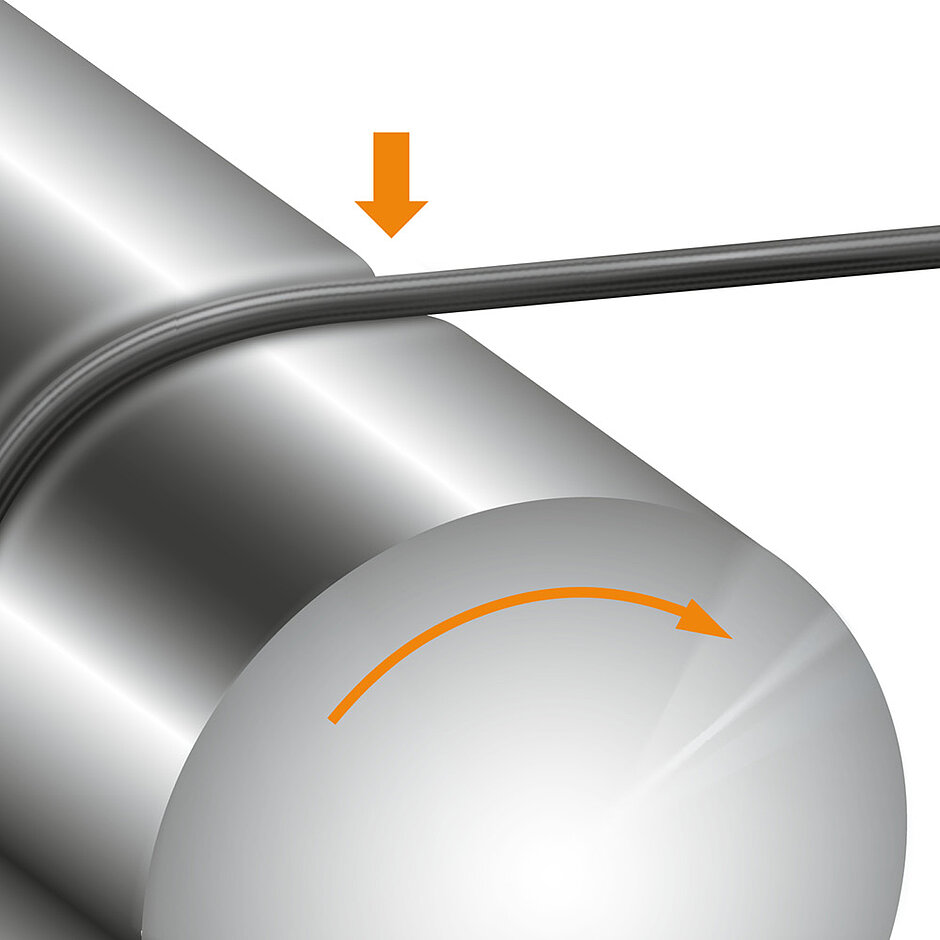

For the processing of filaments carbonprocessing surfaces with the suitable characteristics are produced. Due to the “soft” round-ridged profile, considerable improvements in the process steps are achieved.

Avoiding interruptions of operation

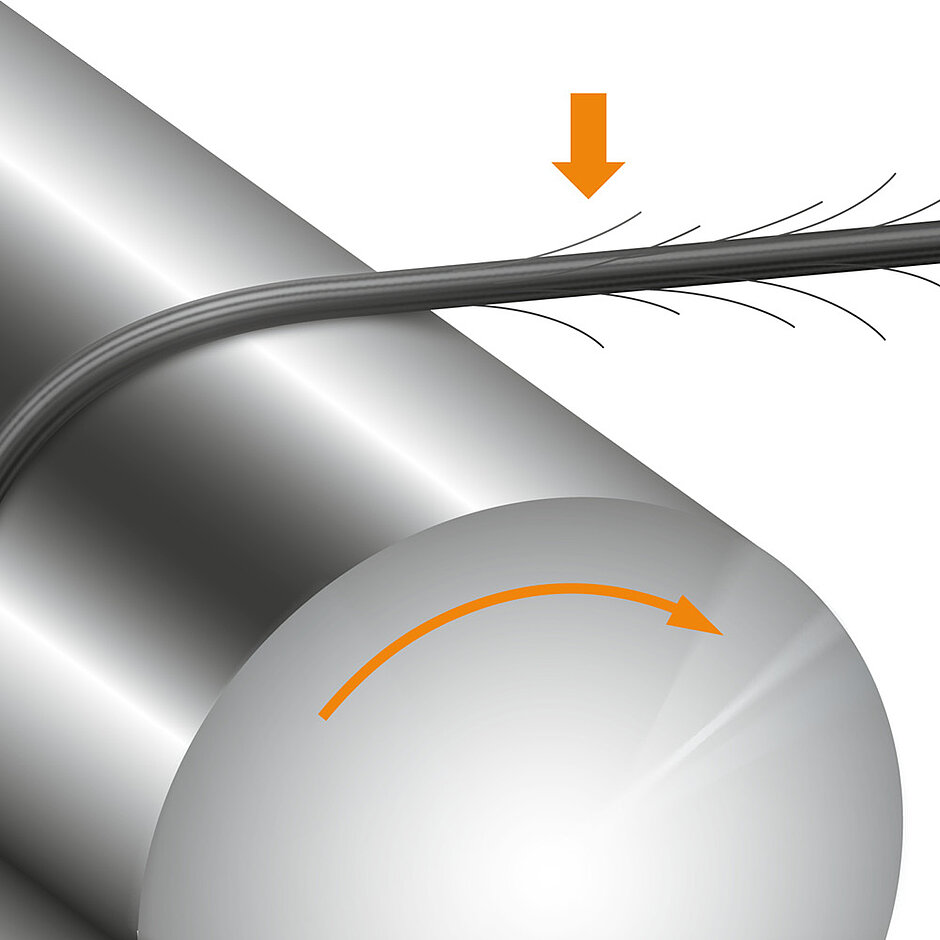

The automated processing of technical fibres such as carbon, glass, basalt and aramid has one common challenge: If the fibres and filaments break, tear, stick or splice during processing, this leads to an interruption of operation. TOPOCROM® coatings prevent these interruptions.

Problem solver in filament processing

The TOPOCROM® carbonprocessing surface has noumerous advantages:

Advantages on the fibres guiding element

- High resistance to wear, corrosion and abrasion

- Longer service life

- Homogeneous surface structure with a round ridged profile

- Capability to transport liquids

Advantages on the composite fibre

- Prevention of splicing

- Prevention of wrappings

- Prevention of dust formation

- Good wettability (avivagen)

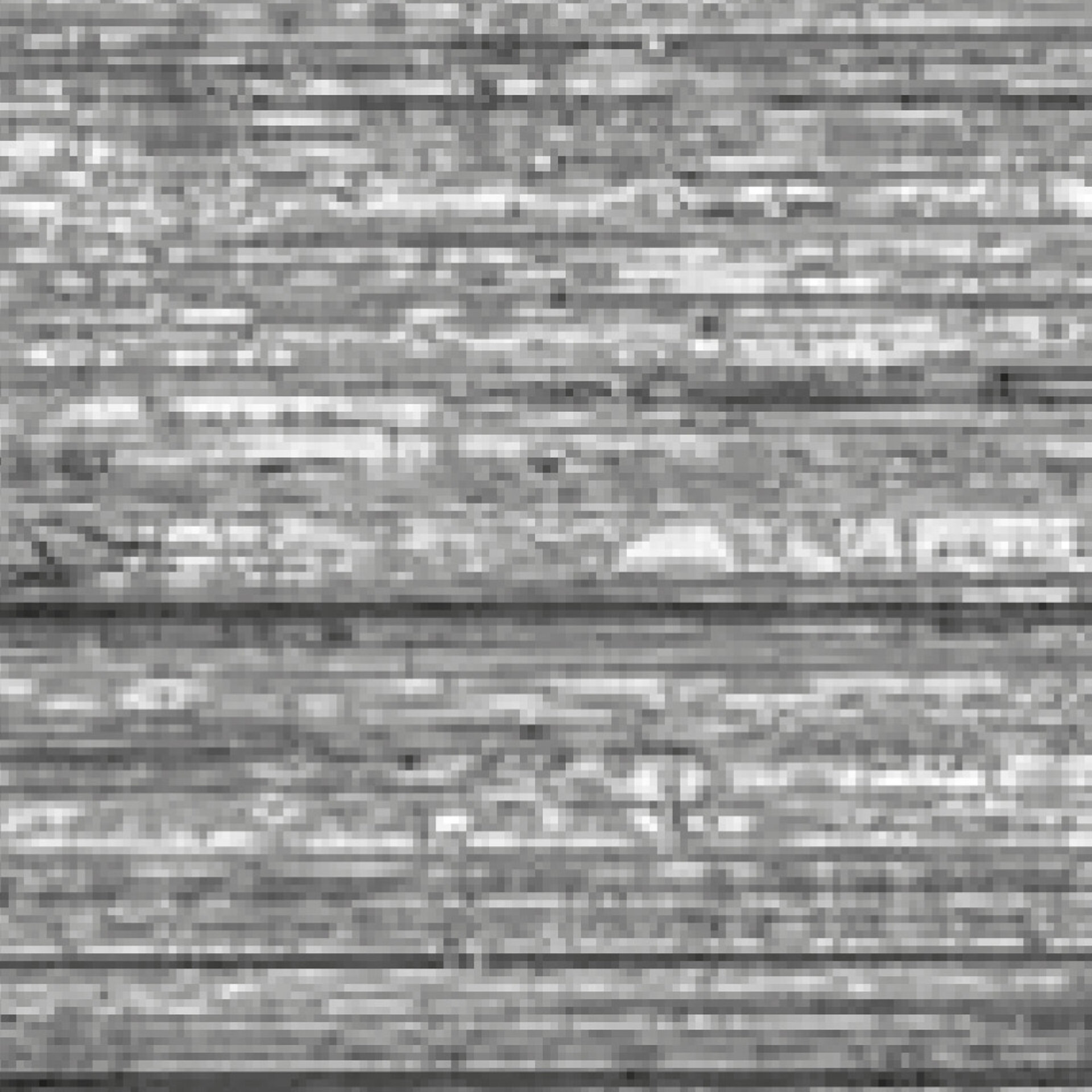

The following microscopic photographs show a ground surface, which was initially shot blast and then hard chrome plated. This conventional surface treatment produces the so-called “orange peel”, which is still used in the textile industry today. The shot-blasting rips open the metallic surface and thereby causes pointed sharp edges “riffs” which can only be unsatisfactorily smoothed out by the following hard chrome plating step.

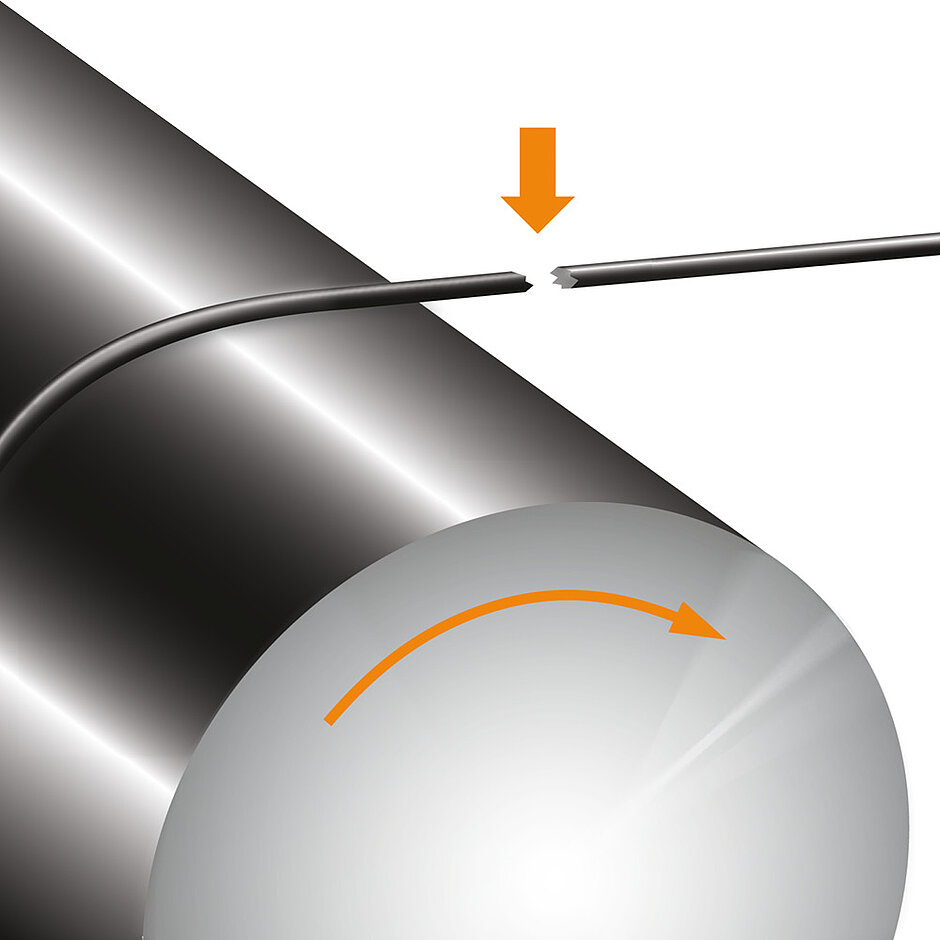

The following images show the same ground surface that has been coated in a reactor using the TOPOCROM® principle. Preparatory roughening processes are not necessary – the surface structure is produced in a single process step. The blasting process step is no longer required. The TOPOCROM® carbonprocessing surface guarantees a fibre-friendly processing of carbon and other high-tech fibers.