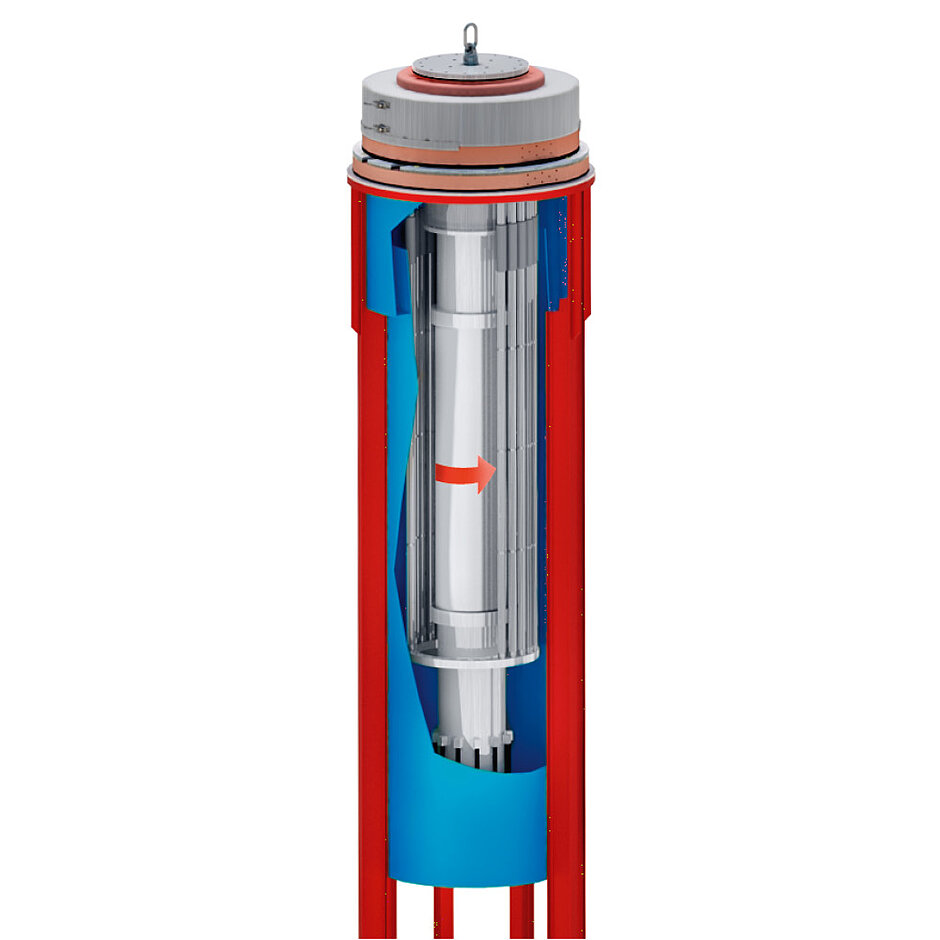

Chrome plating in closed reactors

TOPOCROM® layers are produced according to the closed reactor principle. Reactors with different sizes are available for single item and serial production. This technology enables the generation of structured surfaces in a continuous single process step.

The customised parameters of the coating are saved in the computer. Thus, it is possible to guarantee an exact reproducibility of the desired coating system.

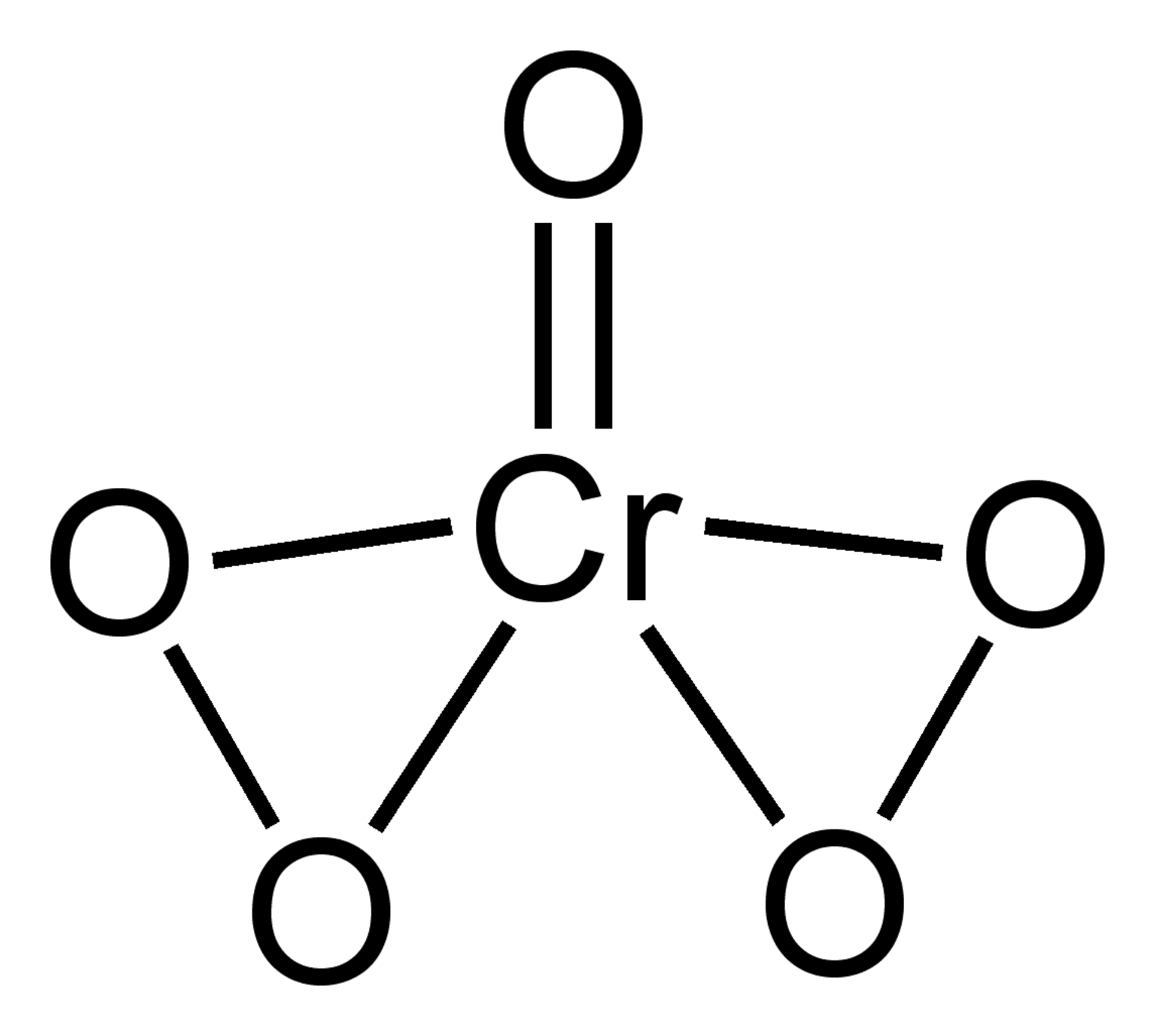

Adjustable surface features

The structured chromium surface can be individually adjusted to achieve properties according to customers‘ demands. The composition of the layer system, the thickness of the layer and the suitable surface structure are thus defined individually and selectively: based on the application and the required characteristics our engineering develops the suitable formula. By means of sample coatings, the results can be controlled for a pilot application.

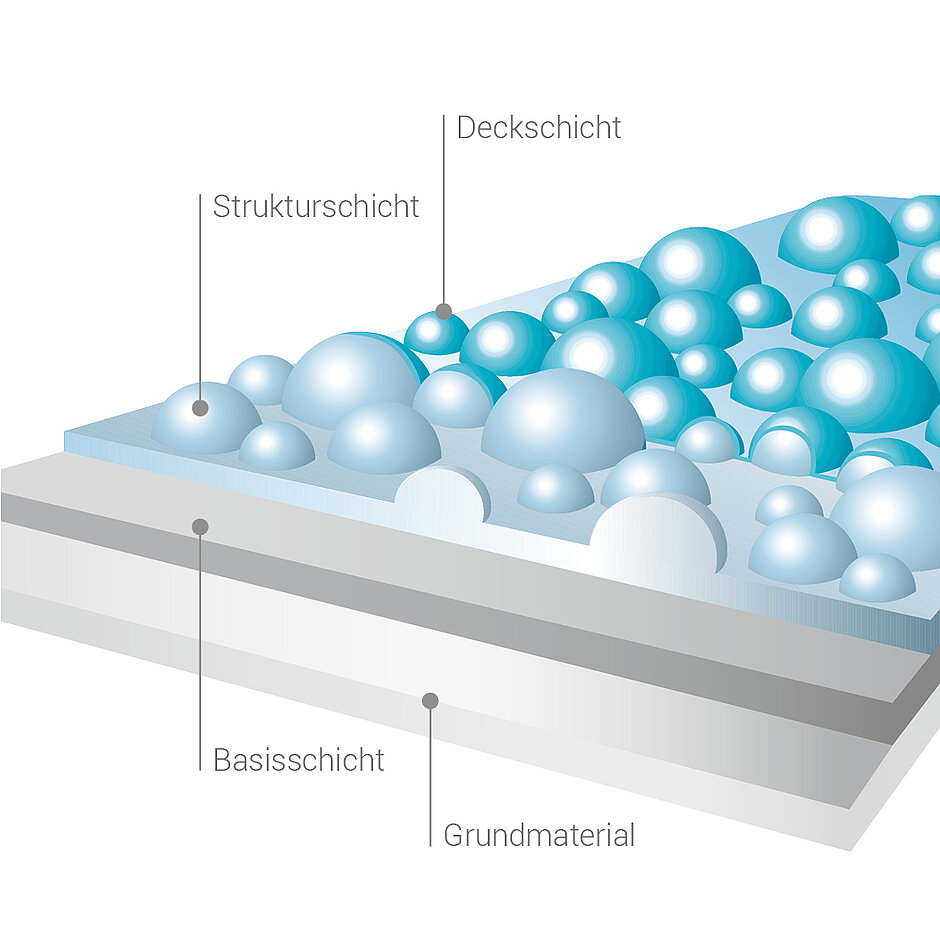

TOPOCROM® layer system

- Top layer

- Structured layer

- Base layer

- Base material