Thanks to the surface properties adapted to the respective task, we have developed a wide range of industrial solutions. The basic principle is always the multi-layer TOPOCROM® layer system, which is designed according to the reactor principle. However, the finished coatings differ in terms of their properties (sliding ability, abrasion resistance, roughness values, grip, liquid transport, wettability, demouldability, forming property, embossing property or texturing).

The different "recipes" and process parameters are developed individually according to the requirements of the customer and stored for computer-aided production. This ensures exact reproducibility at all times.

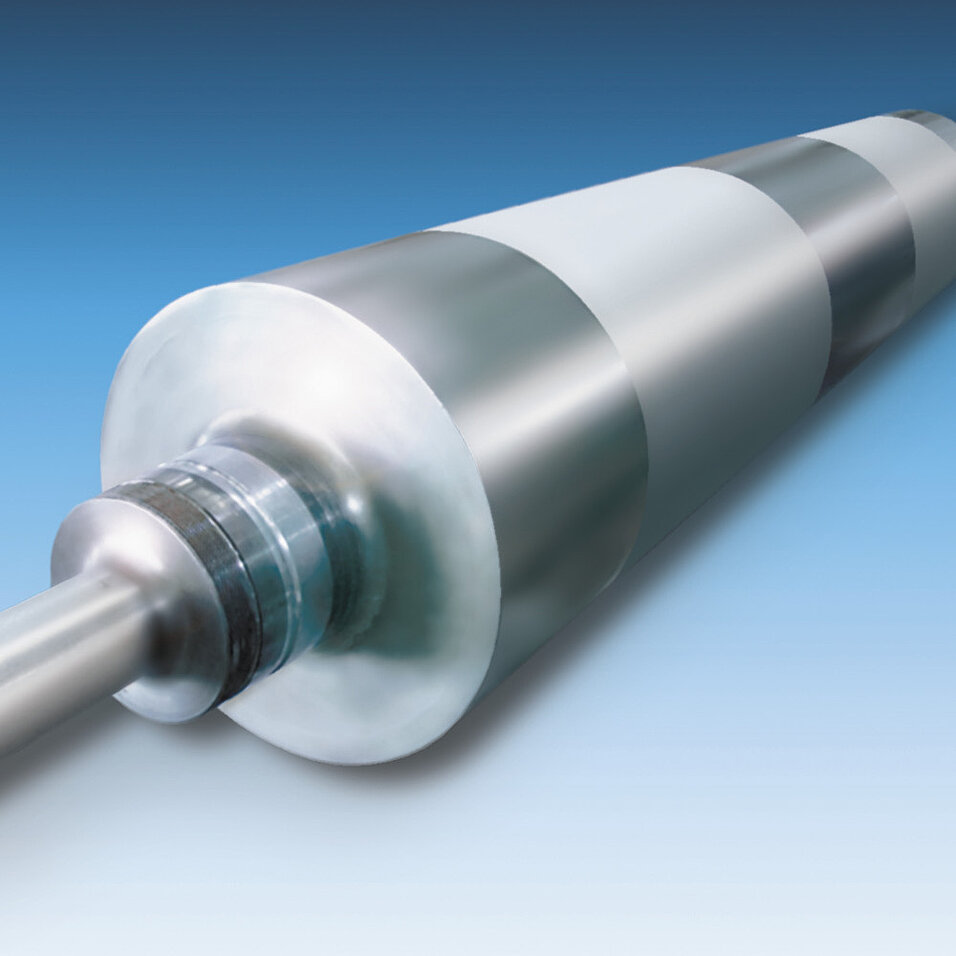

Due to the "soft" topography, the TOPOCROM® coating of filament processing machine components has proven itself very well. The avoidance of filament breakage and splicing, as well as the longer service life of components coated with TOPOCROM® have been proven in numerous application areas.

Application:

Coating of components for carbon, aramid, glass, basalt, chemical or technical fibres/yarns

Practical example:

eyelets, deflection elements, spreading elements, filament guiding bars, rollers, scoop rollers etc.

Further information see carbonprocessing

In this field of application, the exactly definable wettability of the roll surface is used. In dampening systems, dampening rollers must convey precisely defined quantities of liquid. With the TOPOCROM® surface coating this challenge could be solved convincingly and uniquely worldwide.

Further information see rollstructuring

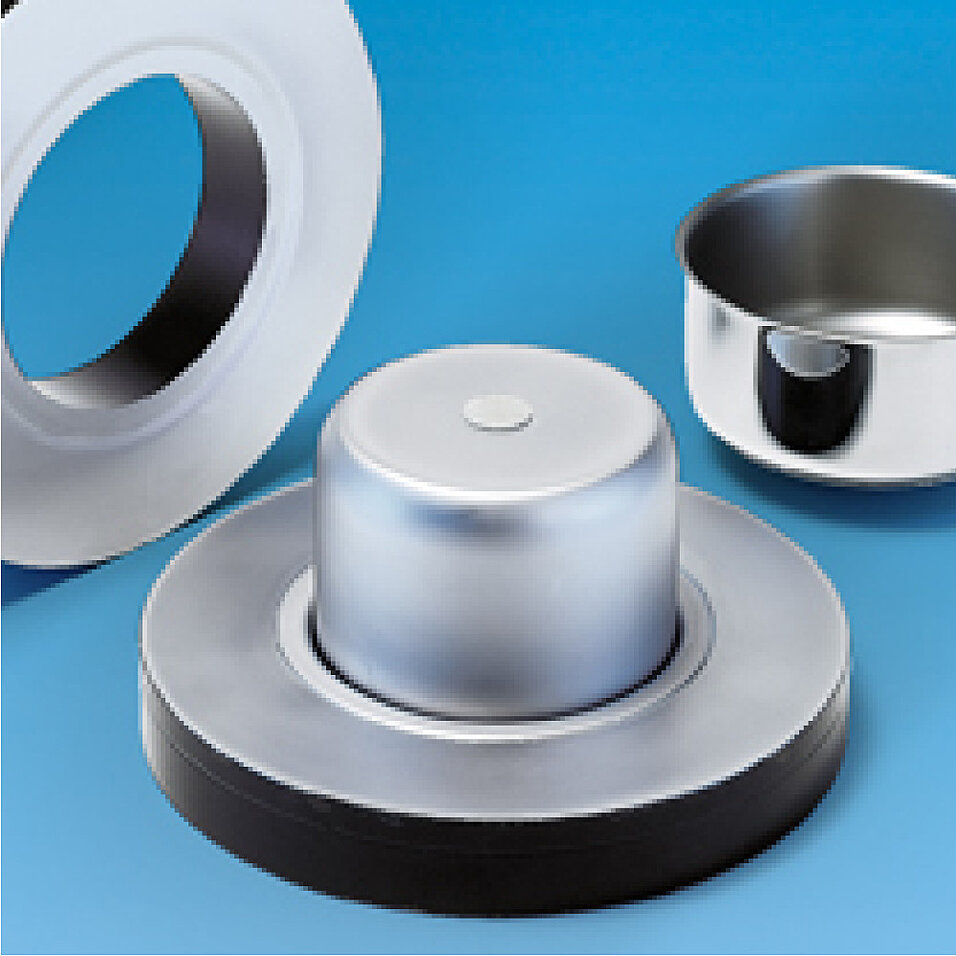

The use of TOPOCROM®-coated male and female dies in the plastic injection moulding technology has been tried and tested for years and has proven itself. Compared to differently coated or structured surfaces, TOPOCROM® achieves significantly better results in various respects: good demouldability, longer service life, faster cycle times.

Application:

Coating of injection and extrusion tools for various types of plastic, fibre-reinforced plastic/composites, compounds, elastomer, rubber, silicon

Practical examples:

cores, ejector pins, cavities, 2-component moulds, mandrels, nozzles, slot dies, screws, plate moulds, forming tools, smoothing rolls, calender rolls

Further information see easyeject

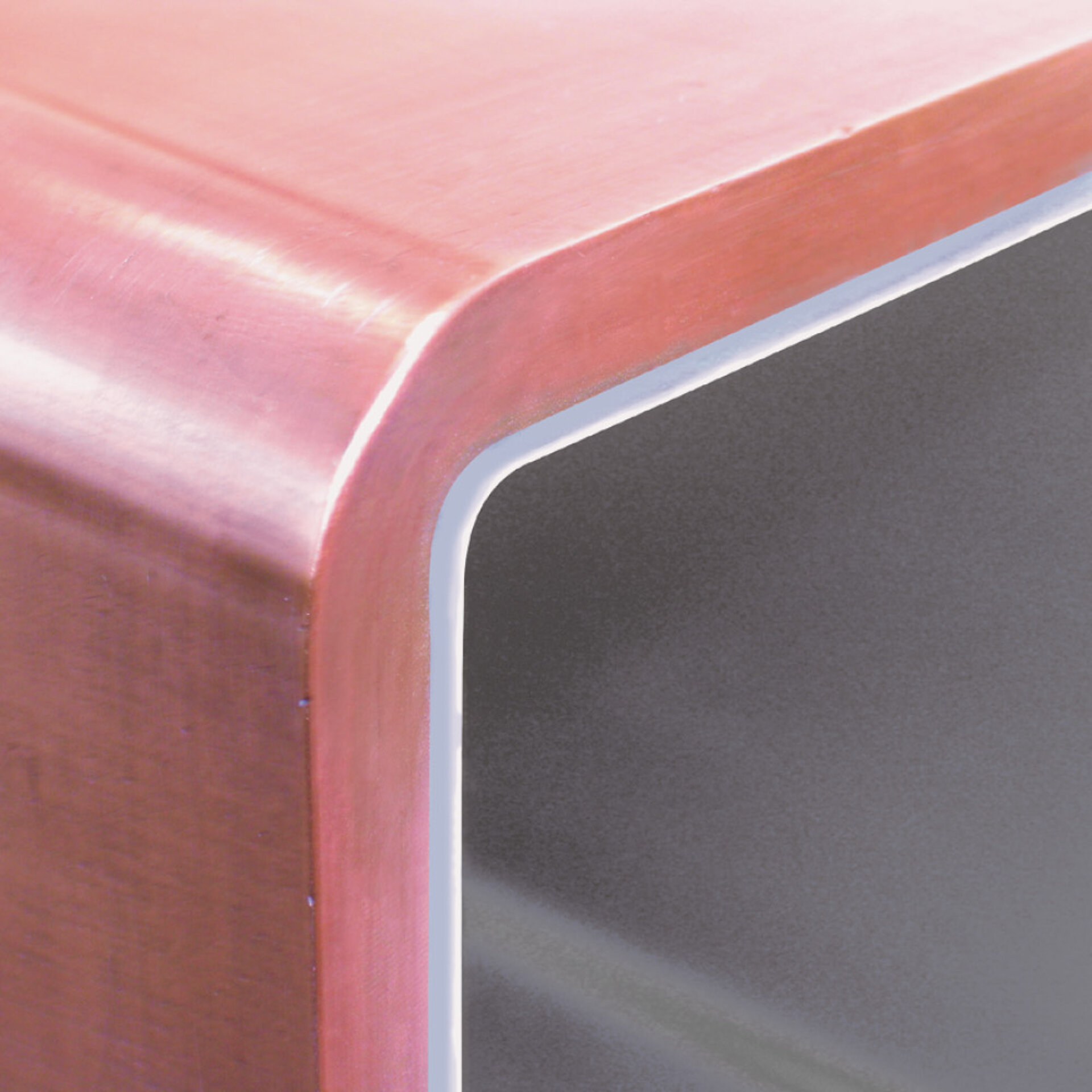

The TOPOCROM® coating shows great advantages in metal sheet forming:

The friction between tool and sheet metal is reduced. The holding down device (with high Ra value) coated with TOPOCROM® holds the sheet metal down in such a way that no stick-slip effect occurs. Lubricant deposits in the recesses between the hemispheres of the surface so that no cold welding effect can occur. The coating thus ensures a long service life of the dies and the holding down device.

The adjustable topography or definable roughness of the coating on feed rollers leads to desired frictional properties (grip). This also prevents the stick-slip effect. Leading manufacturers of sheet feeding machines and straightening machines have their rollers coated by Topocrom. In addition, rolls coated in this way are characterised by longer service lifes.

Further information see rollstructuring

In the automotive industry, car body panels are often processed, which are provided with a structured surface by means of TOPOCROM®-coated skin pass rolls. These sheet metal surfaces improve the forming results and form an ideal basis for modern painting technology.

Further information see systems engineering