More layers, increased resistance to abrasion and corrosion

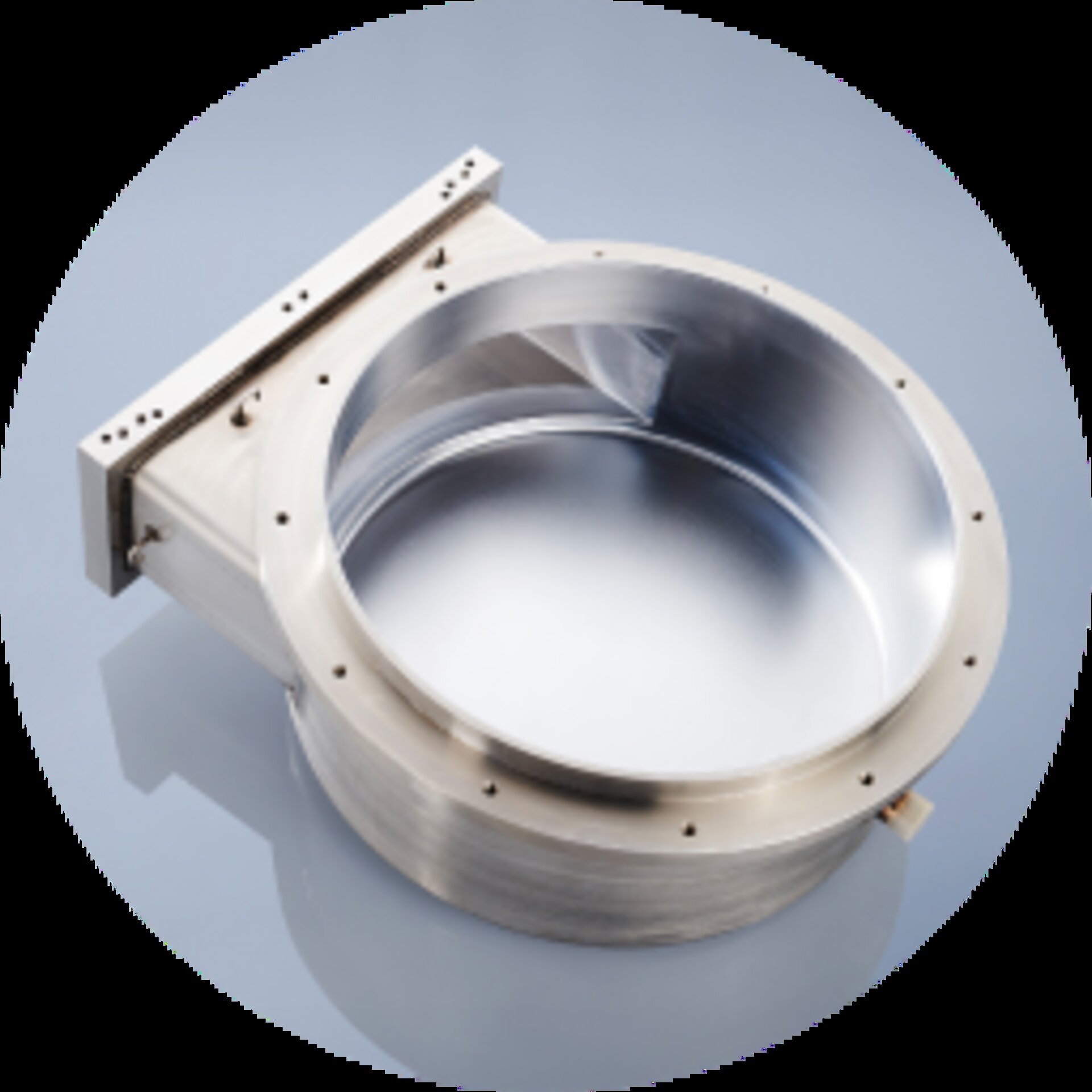

Gradientcrom® is a special TOPOCROM® process that offers excellent protection against abrasion and corrosion. The multi-layer system is typical for this technology. The individual layers are distinguished by different hardness values.

By means of a special deposition procedure in the closed reactors, compression stress arises in the functional surface of the chrome layer.

Areas of application

- Transport pipes for concrete pumps and slurry pumps

- Pipes in the chemical and petroleum industries

- Pipework installations in sewage treatment plants and process technology

- Transport pipes for waste disposal

- Transport of suspensions

- Sugar, pulp and pultiphase mixtures in chemical or food industry

Transport pipes for concrete, sand, gravel or mixture are subject to a high degree of abrasion. Compared to conventionally electroplated or hardened pipes, TOPOCROM® coatings provide considerably longer service life and best sliding abilities. Measurable advantages have been proven in operation. The coating can also be indicated when transporting suspensions in processes in the chemical industry, because abrasion and corrosion are reduced.